Welding advanced armored steel is a challenging task. It requires perfect control over materials and a strategy to handle heat without damaging the metal. In high-stakes industries like defense and security, a single mistake can cause a failure in mission critical equipment.

To avoid these risks, manufacturers need state-of-the-art robotic platforms. These systems offer precision, flexibility, and tracking through advanced automation.

The Challenges of Welding Armored Steel

- Complex Materials: Armored steel contains high levels of carbon and other metals like chromium and nickel. These elements make the steel very strong, but also fragile during welding. The process requires strict supervision to prevent the metal from becoming brittle or cracking.

- Strict Performance Standards: Armored vehicles must withstand extreme stress and provide maximum protection. This means the welds must be perfect—with no holes (porosity), good flexibility (ductility), and high strength.

- Cracking Risks: To prevent cracking, welders usually need to preheat the metal and apply the weld in specific layers. Traditional manual methods often struggle to monitor these temperatures accurately or fix changes in real-time.

Weldobot’s Technology: A Smarter Solution

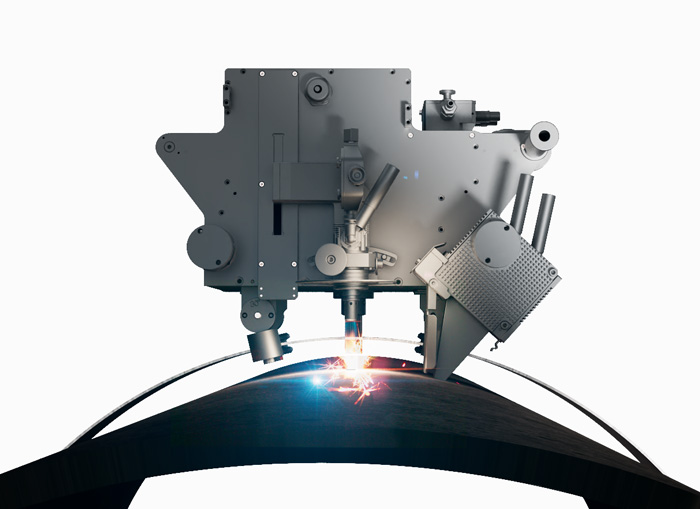

Hybrid Plasma-MIG (SuperMIG®)

Our unique SuperMIG® system combines plasma and GMAW welding into one torch. By controlling current, voltage, and gas flow all at once, the system ensures a stable arc and the perfect weld shape.

Adaptive Path Planning

The robot uses laser guidance to map the joint in real-time. This allows the system to stay on the correct path and maintain the right weld pool, even on curved armor plates.

Automated Process Control

Instead of just reacting to errors, our system monitors the process to prevent issues. It automatically adjusts settings to stop small cracks or defects from forming.

Benefits for Manufacturing

- Stronger Bonds: Uniform welding creates tougher, more impact-resistant armor.

- Flexible Production: The robots can easily switch between making prototypes and mass production.

- Lower Costs: With fewer errors and less waste, the total cost of production goes down significantly.

FAQ: Armored Steel Welding with Weldobot

Q1: What makes Weldobot’s system different?

A1: Weldobot uses the patented SuperMIG® torch combined with laser tracking and real-time control. This delivers strong, consistent welds with very few defects, even on difficult steel grades.

Q2: How does the robot prevent cracking?

A2: The system manages heat very strictly. It keeps the metal at the right temperature and adjusts the welding process instantly to prevent cracks, even in hard-to-weld alloys.

Q3: What are the main business advantages?

A3: Automated welding speeds up production, ensures all data is tracked for safety standards, and reduces the need for expensive rework. It works well for both field repairs and factory production for sectors such as defense, critical infrastructure, and heavy equipment.

Q4: Is the SuperMIG® system compatible with older steel specifications?

A4: Yes. The system is flexible and supports old specifications as well as modern alloys and new regulations. The SuperMIG® can be used with variety of standard robots and welding Power sources.